Derracudas zermatt 20vt,6spd, 351awhp - July 4th drive vid

ok no coffee yet, but its hp a function of tq? other way around? need caffeine bad

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

-

Berserker

-

SeStone

the_natrix wrote:correct. so they limit rpms and probably taper boost as rpms get to the hp limit point.

Yeah, boost tapers hard--something like 60psi+ at 2000rpm, down to nothing at redline. Horsepower is capped at 300, but when you make 300hp from 3000rpm to 8000rpm you have an interesting torque curve ;-).

Sam

SeStone wrote:Yeah, boost tapers hard--something like 60psi+ at 2000rpm, down to nothing at redline.

Sam

for real? 60 psi?!!!?!

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

- speeding-g60

- Posts: 2152

- Joined: Fri Mar 01, 2013 10:46 am

hahah 1/4" should be pleeenty, its what they make nalgene bottles out of, ive spent lots of timing trying to break them

id guesstimate that 1/4" is good for 50-60 psi , i think it would depend more on size of window, a 3/4" x 3/4" window would be strong

a 2"x2" would take a lot less psi to break, if you were to test with the same thickness

id guesstimate that 1/4" is good for 50-60 psi , i think it would depend more on size of window, a 3/4" x 3/4" window would be strong

a 2"x2" would take a lot less psi to break, if you were to test with the same thickness

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

- speeding-g60

- Posts: 2152

- Joined: Fri Mar 01, 2013 10:46 am

than 1/2" will be plenty strong even for somethign that size, yeah do it itll look sweet

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

-

teamplatto

just to specify something about the rally cars.

We're not limited in horse power, we're limited in air flow. On the compressor intlet, we have a 34mm restrictor which is placed 25mm from the impeller.

Again we're restricted on engine displacement.

That's why we make a lot of torque. Every body know that a turbo has its limit, even more with a 34mm restrictor in the mouth. So lets talk about the k26, it produces its max gain of HORSEPOWER @ about 15 psi of boost (with restrictor). Past this point you make less HORSEPOWER for each psi of boost compared to the torque you produce. That's exactly why we boost as high as 22-24 psi of boost. We're doing about 270-280 HP but we get 350 pounds of torque from 2500 rpm till 7000 rpm.

I know some subaru guys into rally who run as high as 28-30 psi with a 34mm restrictor.

FYI engine is 20vt mc2, headers, cam, 3 inch exhaust, water injection, 30 deg timing at peak boost and rpm.

my 2 cents.

We're not limited in horse power, we're limited in air flow. On the compressor intlet, we have a 34mm restrictor which is placed 25mm from the impeller.

Again we're restricted on engine displacement.

That's why we make a lot of torque. Every body know that a turbo has its limit, even more with a 34mm restrictor in the mouth. So lets talk about the k26, it produces its max gain of HORSEPOWER @ about 15 psi of boost (with restrictor). Past this point you make less HORSEPOWER for each psi of boost compared to the torque you produce. That's exactly why we boost as high as 22-24 psi of boost. We're doing about 270-280 HP but we get 350 pounds of torque from 2500 rpm till 7000 rpm.

I know some subaru guys into rally who run as high as 28-30 psi with a 34mm restrictor.

FYI engine is 20vt mc2, headers, cam, 3 inch exhaust, water injection, 30 deg timing at peak boost and rpm.

my 2 cents.

-

blacksmith

-

gruppe5

While I will agree that the Dahlback manifold will not add the most power( I sold ALOT of these) , I have to say that not everything done to a racing engine is done in the name of power. Alot of people purchase products based off of high flow numbers or high whatever numbers without doing any real research. Making power is easy, making long term, consistent power is another thing. The dual plenum manifold has its place in a line of of modifications and tuning procedures that are meant to take advantage of it. Its kind of like DLC coated piston pins, your not going to make any more power just because you do it, but it allows you keep the pin cooler in turns help keeping oil temp under control and combustion chamber heat in check, but if you don't do the other things needed to take full advantage of it them you won't realize the benefits. You could slap on an oil cooler and say that it does the same thing but it does not, it is just one piece of the puzzle. Quite a few manifolds out make power just due to the fact that they have a larger plenum, they would like to attribute it to "superior" design and such but its just not so, and flow numbers from a flow bench pulling a vacuum don't tell you anything. The purpose of the dual plenum is to ensure equal air flow to each cylinder, extra/more power is sometimes a byproduct of that. That power may not be "free", you may have to adjust other things to see it, sort of like when you coat a combustion chamber some people melt pistons and then say the product doesnt work, never having made any other changes like that important thing we call "timing". Everyone likes to buy the item with the best "numbers" not realizing that they are chasing their tail. Products like the SEM manifold were designed by competent people using the tools they have correctly and the price reflects that.

-

derracuda

derracuda wrote:well, i'd put up some pics, but photobucket is down for maint. i'm going to bedi'm tired.

set your alarm and get up early, we want pics!!!!

24v-VR6T-CQ BEAST http://www.theprojectpad.com/viewtopic.php?f=11&t=193#p37887

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

16v-ABA-T VEMS O1E ETC 4Kq http://www.theprojectpad.com/viewtopic.php?f=11&t=201#p38264

-

Longitudinal

- Posts: 107

- Joined: Sun Mar 03, 2013 1:29 am

derracuda wrote:under pressure, i believe it will act a complete different way. reason? one way it's being pushed through, filling cavities and voids, and will follow certain shapes and directions, the other way it's being pulled through and will not draw in all the same ways....

I *believe* that the way to think of it is that the air is always being "pulled" through the engine, whether NA or turbo, on or off boost; the air is not being "pushed" at any time, but only compressed downstream of the turbo. The turbocharger or supercharger causes a drastic increase in the density of the air, but the air acts the same way because it is still just a fluid. I wouldn't expect oil to behave differently from mercury flowing through the intake only because their densities are different, so I wouldn't expect less dense or more dense air to act differently.

On this reasoning, which I admit may be faulty, I'd say that the constrictions on intake manifold design are based only on displacement, port design and target RPM, not density of the air charge.

-

cuatrokoop

- Posts: 271

- Joined: Thu Mar 07, 2013 11:27 pm

- Location: Findlay, OH

-

derracuda

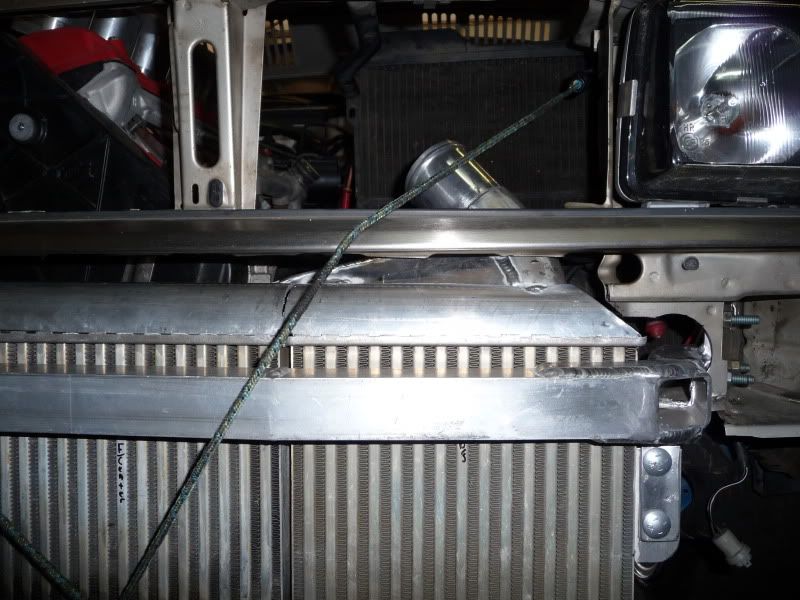

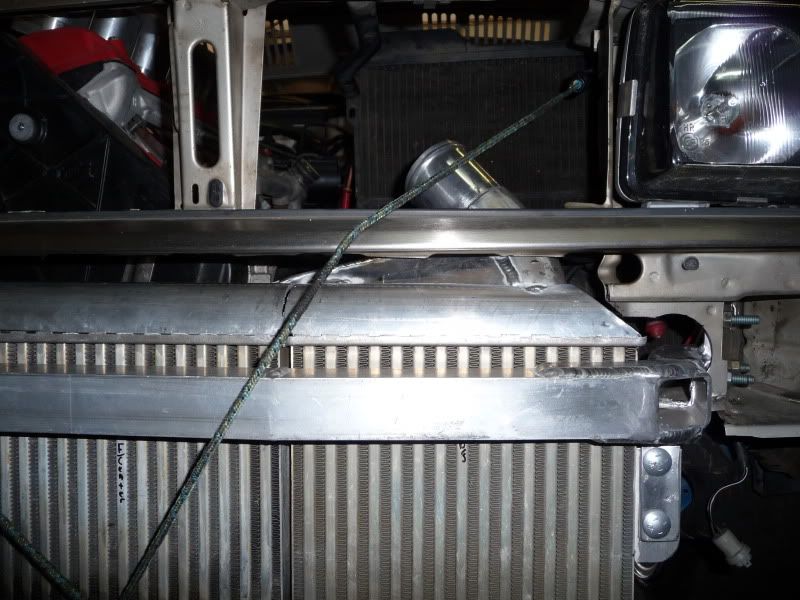

oookay. this all i've gotten done in the last couple days. kinda had some holdups with other things going on around here...

continued with the intercooler progress...

mm, i like long exposure pics

next up.. header....

i stripped the turbo and junk off the pass. side of the engine to prep for header time..

i bought about half the stuff to build it, i just got too busy to be able to commit to making one right now, so i did the unspeakable... bought an ebay header and put it on.

i know it's not a super high quality piece, but it'll work for now so i can get the car together and running and making some power. Hank's URQ has been making some decent power on the same thing, so i figured it couldn't hurt 8)

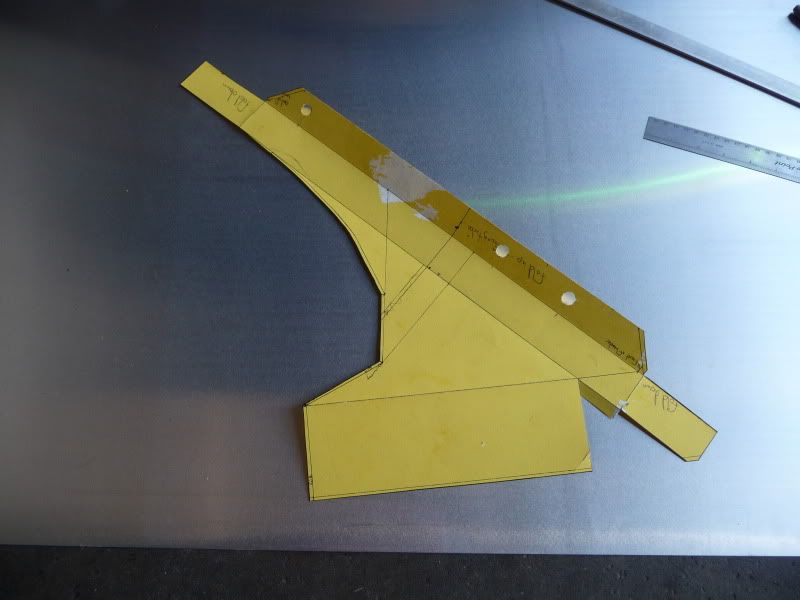

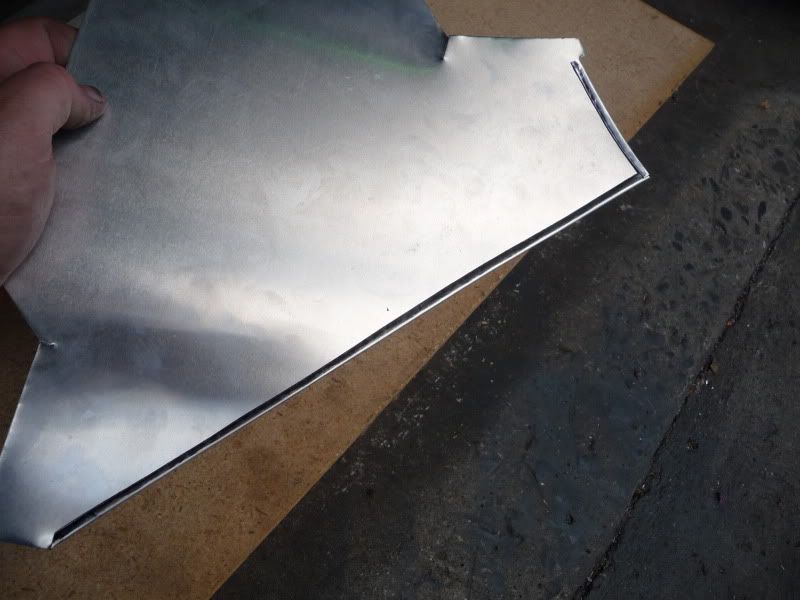

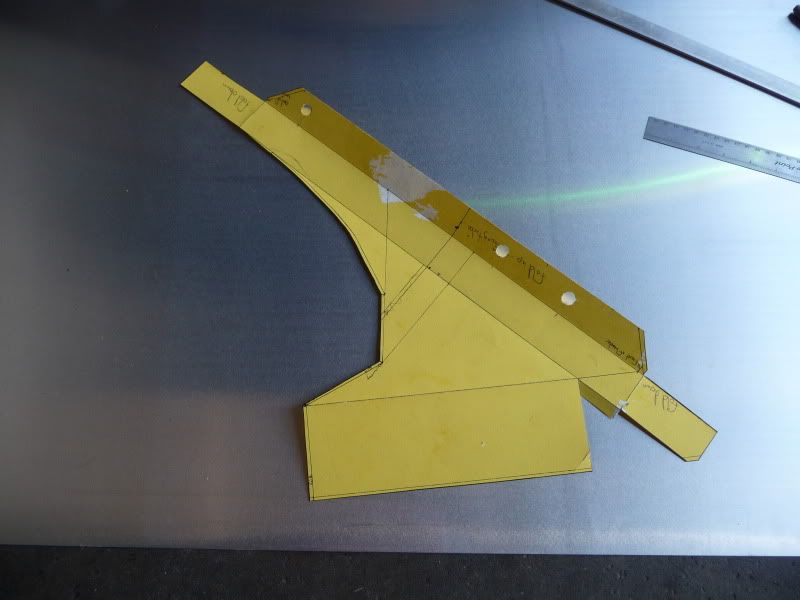

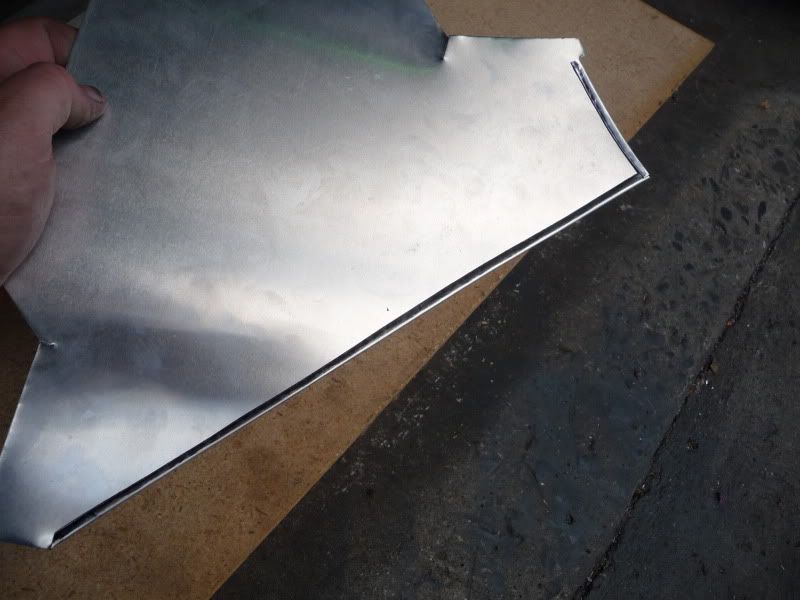

i wanted to make some heat shields to keep things cooler and to last longer, and this is as far as i've gotten tonight.

the mounting holes are slotted from the bottom to make it easier to get on and off.

i am still working on a part to go around the WG and then over the top of the DP, and between the turbine and compressor sides of the turbo.

i wonder sometimes why i have so much crap... and then i remember why when i get to building something. i need misc. pieces like this

i also had some 3" SS pipe to start making the DP as well.

parting overall shot for the night..

there will be a turbo support brace made too...

and lastly.. i settled on some wheels.

Ronal R28. 17x8.5" ET35 with 215/40/17's for a little bit of stretch... 8) (blame Casey!!)

i won't be running the euro T/A's, i just had one for a test fit. i have some dunlop Direzza Star specs on the way 8)

continued with the intercooler progress...

mm, i like long exposure pics

next up.. header....

i stripped the turbo and junk off the pass. side of the engine to prep for header time..

i bought about half the stuff to build it, i just got too busy to be able to commit to making one right now, so i did the unspeakable... bought an ebay header and put it on.

i know it's not a super high quality piece, but it'll work for now so i can get the car together and running and making some power. Hank's URQ has been making some decent power on the same thing, so i figured it couldn't hurt 8)

i wanted to make some heat shields to keep things cooler and to last longer, and this is as far as i've gotten tonight.

the mounting holes are slotted from the bottom to make it easier to get on and off.

i am still working on a part to go around the WG and then over the top of the DP, and between the turbine and compressor sides of the turbo.

i wonder sometimes why i have so much crap... and then i remember why when i get to building something. i need misc. pieces like this

i also had some 3" SS pipe to start making the DP as well.

parting overall shot for the night..

there will be a turbo support brace made too...

and lastly.. i settled on some wheels.

Ronal R28. 17x8.5" ET35 with 215/40/17's for a little bit of stretch... 8) (blame Casey!!)

i won't be running the euro T/A's, i just had one for a test fit. i have some dunlop Direzza Star specs on the way 8)

- speeding-g60

- Posts: 2152

- Joined: Fri Mar 01, 2013 10:46 am

-

derracuda

well, the header doesn't look bad... but really, i wanna kill heat as best i can. long term it makes a difference. the best part about this header is, once it craps out on me, i can use it to make a jig.... then everything will work the same.

i have a decent set of gloves for welding... and a friend has been doing the welding. he welds for a living, and some of the stuff has been giving him a hard time even, so i'm glad it's not me right now. i just need to get it done, not practice how to ruin stuff i've been planning for months

i have a decent set of gloves for welding... and a friend has been doing the welding. he welds for a living, and some of the stuff has been giving him a hard time even, so i'm glad it's not me right now. i just need to get it done, not practice how to ruin stuff i've been planning for months

- speeding-g60

- Posts: 2152

- Joined: Fri Mar 01, 2013 10:46 am

Looks good Derek. I love seeing progress, even if it is on someone elses project. Hank's header held up surprisingly well. He dressed up some of the welds and ran beads on the runners inside of the flange which I think helped with cracking at the flange itself. I think that getting the flanges milled flat also helps with initial stress. Heck they are almost throw away parts at what you have into them. I like how the I/C turned out. Looks like you ought to run pretty hard without heat soaking. Nice!!

now don't go blamin' that stretchin crap on me! I had to to make the wheels fit  That motor is looking great though!

That motor is looking great though!

That motor is looking great though!

That motor is looking great though!Casey O

Current Attire:

- 2007 Audi A3 3.2 quattro

Past Projects:

- 07 Cooper S - 91 200 20vt - 91 90 20v - 85 4000CS - 96 Audi Cabriolet 5 Spd - 02 A4 1.8T - 91 V8 5 Spd - 01 A6 2.7T 6 Spd Sport - 86 5000CS - 91 100

Current Attire:

- 2007 Audi A3 3.2 quattro

Past Projects:

- 07 Cooper S - 91 200 20vt - 91 90 20v - 85 4000CS - 96 Audi Cabriolet 5 Spd - 02 A4 1.8T - 91 V8 5 Spd - 01 A6 2.7T 6 Spd Sport - 86 5000CS - 91 100

-

death 4kqt