Page 1 of 5

Zerb's 90Q 07K...Intake manifold fabrication

Posted: Wed Mar 12, 2014 9:13 pm

by Zerb

well, ditched the VR on more or less an impulse idea a few weeks ago and havent looked back since. with that being said, i dont have much to share just yet...but the ideas are flowing and the parts are ordered from Iroz, so this should get going sooner then later.

Plans...use same turbo ive had, 6765 (which needs a seal job which means itll be a 6766 on its return) to make hopefully a metric fuckwad of power.

Head will get valve springs, and possibly cams if they are available once this project is done. custom manifolds of course.

Motor will get rods, most likely IE Tuscans, JE pistons and apparently a $1,000 TTRS crankshaft. i was told that cast cranks in the 4 cylinder 20v's didnt handle too much power. but mine seemed to be fine with 600+ for a while there. but i would rather not risk it this time around.

what the motor looks like. from a 2012 jetta, 18k on it. traded my VR for it.

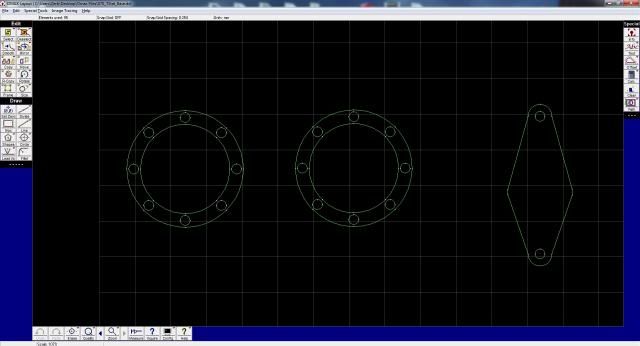

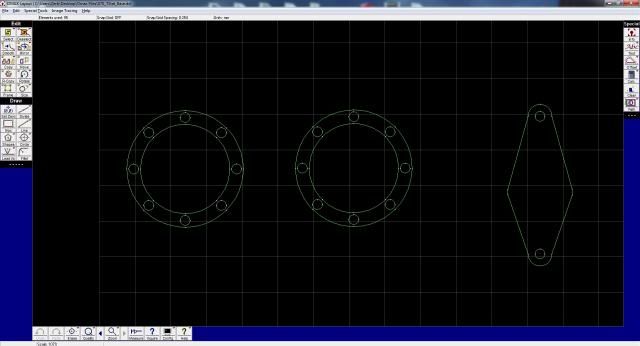

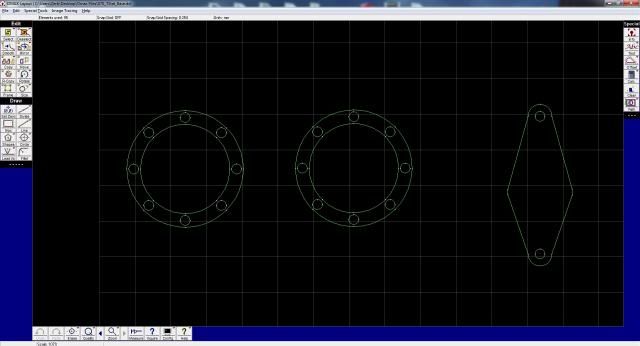

and a sneak peak of the layout of some parts ill get cut on a waterjet for the cooling system, because i need to -AN all the things.

Re: Zerb's 90Q...07K it is

Posted: Wed Mar 12, 2014 9:29 pm

by Audilard

Very nice. Sort out all of the 80/90 setup issues for the rest of us!

Re: Zerb's 90Q...07K it is

Posted: Wed Mar 12, 2014 10:17 pm

by glibobbo21

Darin, Its all the same or better with a type 89 chassis. Compared to a type 85 thats is.

Re: Zerb's 90Q...07K it is

Posted: Wed Mar 12, 2014 10:18 pm

by glibobbo21

Its catching on ;-)

Re: Zerb's 90Q...07K it is

Posted: Thu Mar 13, 2014 6:06 am

by mushasho

Bummer your block didn't come with a forged crank...

Sent from my HTC One using Tapatalk

Re: Zerb's 90Q...07K it is

Posted: Thu Mar 13, 2014 6:34 am

by chaloux

Oh heck yeah! The more the merrier

Re: Zerb's 90Q...07K it is

Posted: Thu Mar 13, 2014 6:44 am

by Zerb

mushasho wrote:Bummer your block didn't come with a forged crank...

Sent from my HTC One using Tapatalk

Super bummer. But I'm pretty sure it was almost an impossibility considering the model year of this motor. Pretty crazy how vw just seemed to sprinkle the forged cranks in there from 05-08

Sent from my SAMSUNG-SM-N900A using Tapatalk

Re: Zerb's 90Q...07K it is

Posted: Thu Mar 13, 2014 7:41 am

by speeding-g60

they did it then realized how much $$$$ they could save skrimping on it so they went cast.

and, for the record, have beaten up cast cranks just fine with no ill effects. in the past. and my backup is cast not forged.

Re: Zerb's 90Q...07K it is

Posted: Thu Mar 13, 2014 7:57 am

by Zerb

speeding-g60 wrote:they did it then realized how much $$$$ they could save skrimping on it so they went cast.

and, for the record, have beaten up cast cranks just fine with no ill effects. in the past. and my backup is cast not forged.

see, i have had the same experience with the cast cranks as well. i always had a stock 92.8mm 2.0l crank in my 20V and i never had any issues. i have seen on at least one occasion though...guy over on vortex with an AWD swapped mk3 2.5L...where the cast cranks have actually broken.

Re: Zerb's 90Q...07K it is

Posted: Thu Mar 13, 2014 3:00 pm

by Audilard

glibobbo21 wrote:Darin, Its all the same or better with a type 89 chassis. Compared to a type 85 thats is.

I'm sure each car will be different, but I'll be curious to see if a B4 radiator will work and if those B4 fans will fit as well, turbo to intercooler to IM setup, the odds and ends of a swap like this. Power steering setup if not electric. Water and oil lines. There is a lot of little fab work that will have to happen.

It's the little things that make this a bigger project than anticipated if you don't have fab skills.

Re: Zerb's 90Q...07K it is

Posted: Thu Mar 13, 2014 3:09 pm

by Zerb

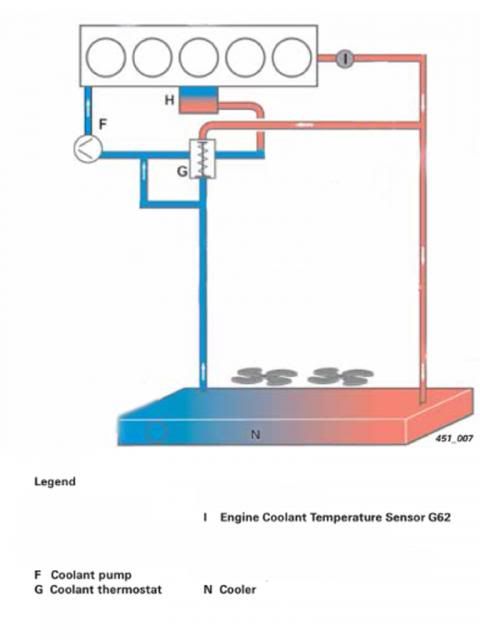

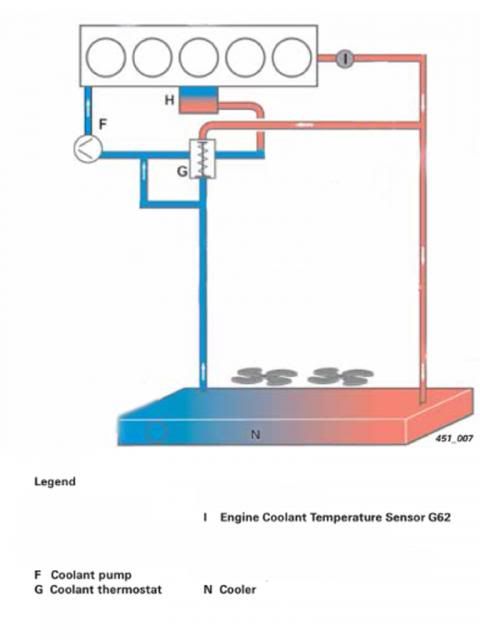

i will measure what i can as far as radiators and fans goes, but i will be using the radiator that i currently have...aluminum double pass universal from SBC. cooling system will be all AN hoses though thats for sure. something like this...

power steering, i did look into the electrical MR2 stuff, but in the end i think i will just go with what hanks done with the custom PS pump bracket and dual pulley system. im told these motors have an issue with tossing belts off at a certain rpm, so the pulley that he machines with a bit deeper grooves in it would i assume help that issue as well.

Re: Zerb's 90Q...07K it is

Posted: Thu Mar 13, 2014 3:20 pm

by Audilard

Are you fabricating your own IM and EM or will these be Iroz units? I believe minor mods are needed to his current I5 intake manifold for it to work.

Keep it up! Can't wait to see this running.

Re: Zerb's 90Q...07K it is

Posted: Thu Mar 13, 2014 3:25 pm

by Zerb

that i will be making myself. using his intake plenum baseplate and intake manifold head flange.

also in regards to the oil pan setup, i may try and see if i can make a custom crossmember section of the subframe up front there and get away with that versus using hanks pan. not that it isnt a beautifully made piece, but in the end that $900 can buy me a set of JE pistons. IF i can get the subframe mods to fit the pan, i would still attempt to weld some sort of trap door's in there due to the way the oil pump pickup will be with a longitudinal setup

Re: Zerb's 90Q...07K it is

Posted: Thu Mar 13, 2014 3:54 pm

by Audilard

Are you keep the valve cover. Looking through the diagrams of it, it seems to be a nice built in oil separator/breather, but will it fit under the hood?

Re: Zerb's 90Q...07K it is

Posted: Thu Mar 13, 2014 4:24 pm

by Zerb

Valve cover will be billet so I can run AN hoses off of it to the catch can.

Sent from my SAMSUNG-SM-N900A using Tapatalk

Re: Zerb's 90Q...07K it is

Posted: Thu Mar 13, 2014 9:12 pm

by PRY4SNO

Subscribed for updates.

This is going to be awesome.

Re: Zerb's 90Q...07K it is

Posted: Sat Mar 15, 2014 11:00 pm

by Zerb

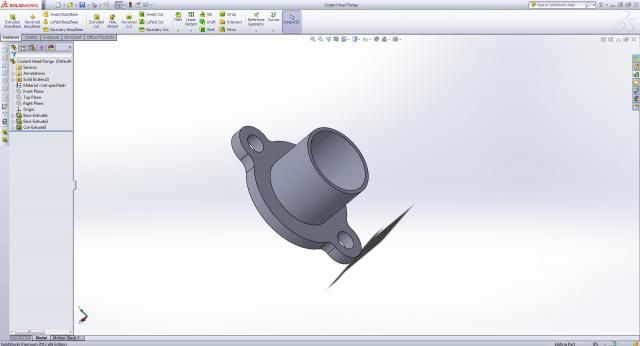

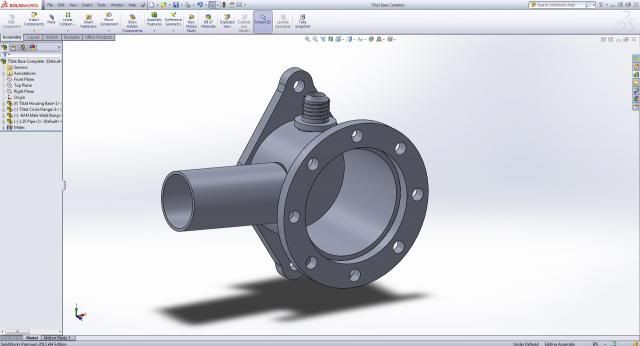

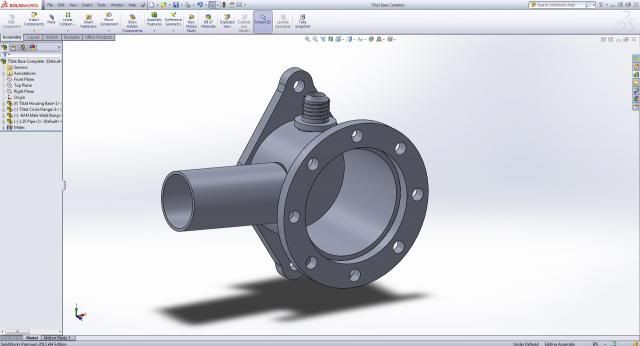

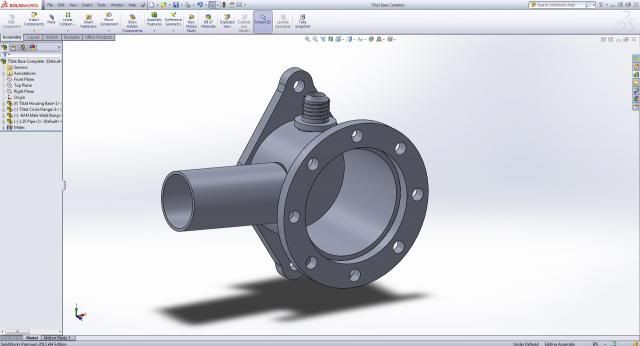

So, no hard parts just yet. but got the cooling system pieces out of my head and onto the computer the best i can so far, lol.

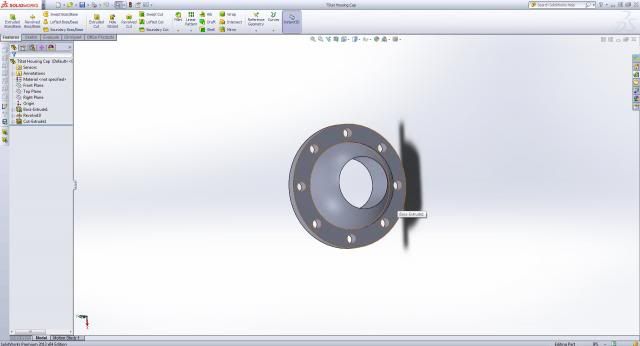

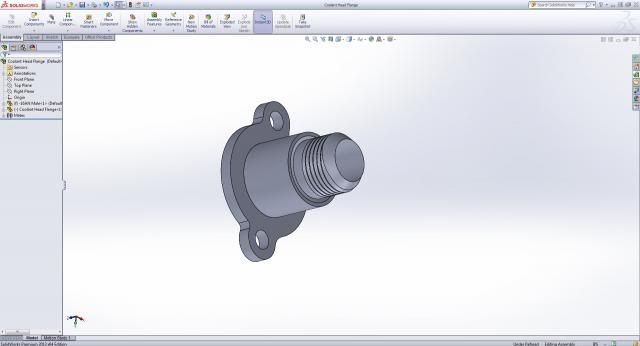

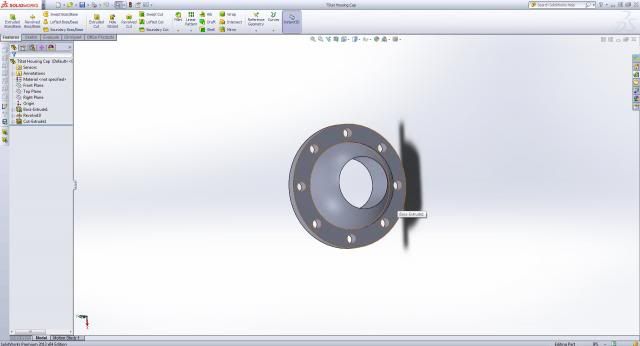

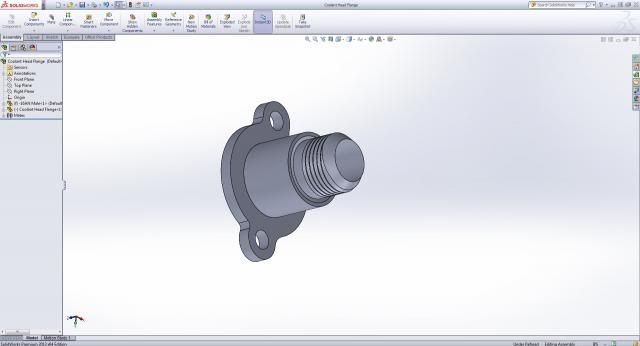

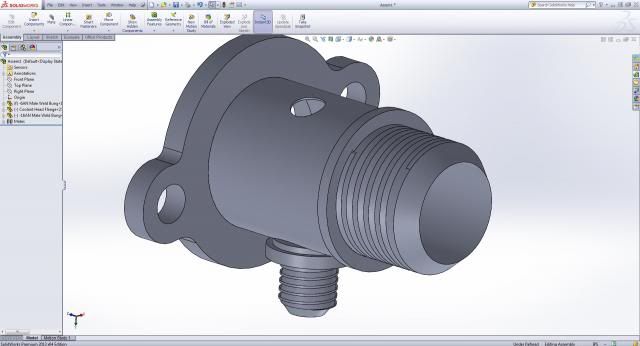

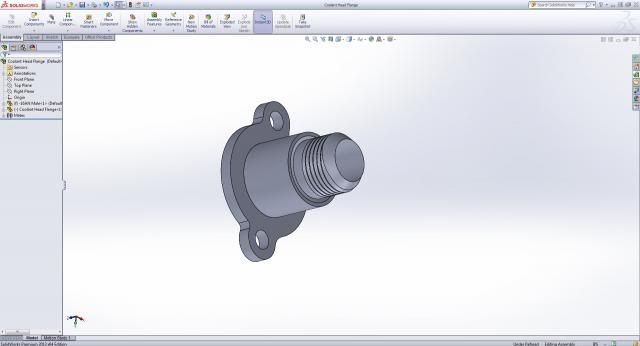

the coolant head flange, made it in a 2D program since it will be cut on a waterjet but wanted to learn more solidworks so i made the almost final piece there...minus the -16 male bung that will be welded to the end of that tube. tube will be 1.5"OD aluminum, will be a slip fit once the lower flange is cut, then just weld and done.

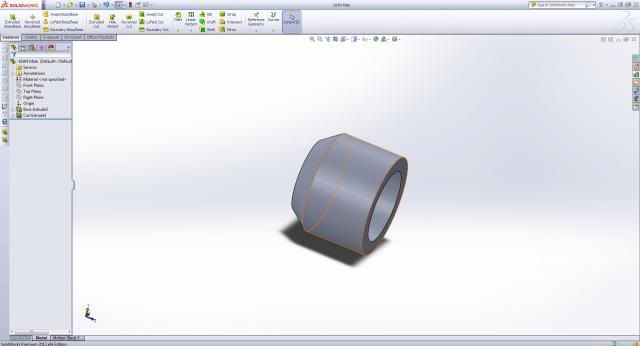

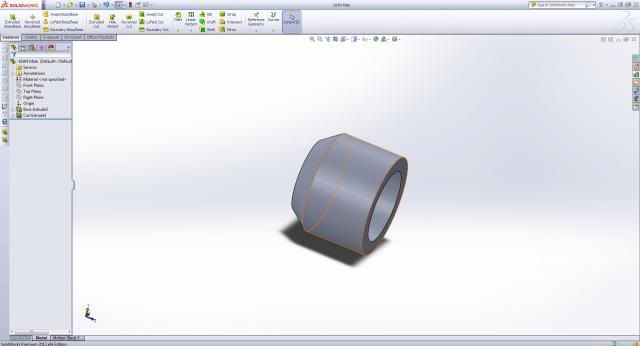

this is as far as i got with the -16 male bung, couldnt figure out quite how to thread it...gave up since its midnight.

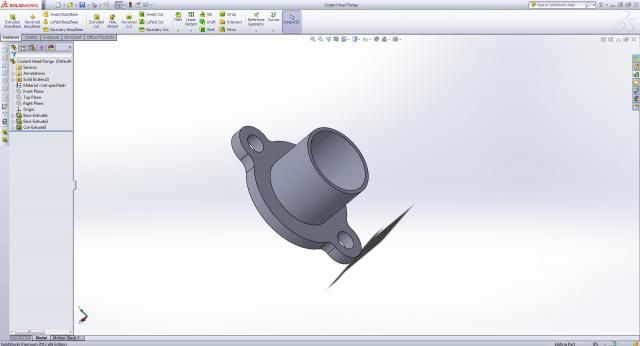

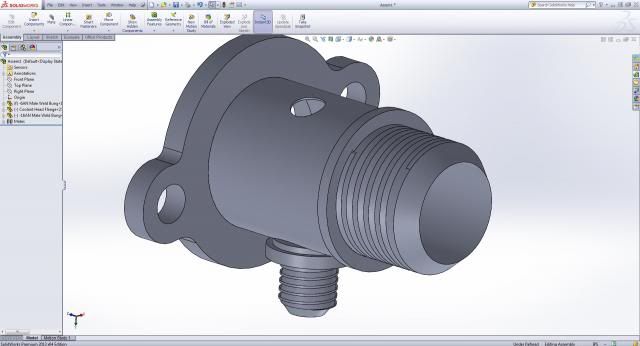

this is the general idea of what the TStat housing will look like when done. that hemisphere will be a 2.5"OD aluminum hemisphere, drill hole...weld -16 bung to it. the lower section that you see with all the holes will be cut out on the waterjet, 2.5"OD center hole of course, weld together then you have the top. the lower section that will house the stat and the pipe that gets fed from the water pump i havent attempted to make yet, bit more complicated of a piece...maybe tomorrow.

Re: Zerb's 90Q...07K it is

Posted: Sun Mar 16, 2014 10:41 am

by Zerb

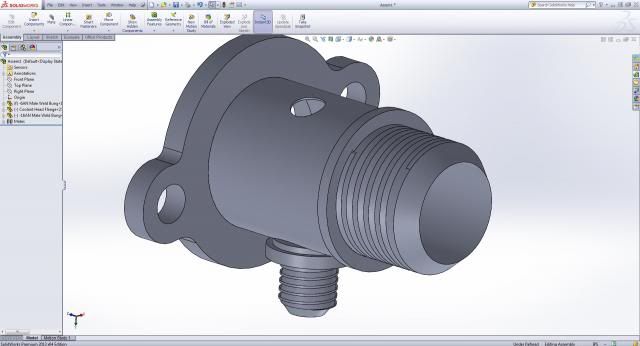

not exactly perfect, but the idea is there just for proof of concept...and its always fun to learn some more solidworks

forgot to add the -6 bung for the tstat bypass. and the hole for the coolant temp sensor. hopefully getting some parts cut this week and can begin making this stuff a reality.

annnnnnnnnnnnnd, this is the beginning of the tstat housing base.

Re: Zerb's 90Q...07K it is

Posted: Sun Mar 16, 2014 4:15 pm

by chaloux

I'm very much looking forward to your take on the 07k given your 1.8t results

Re: Zerb's 90Q...07K it is

Posted: Mon Mar 17, 2014 2:04 pm

by glibobbo21

been there with trying to mod a subframe for the old pan...couple issues I saw.

1. the engine does not stand almost vertical like the vw did. so i dont know the the windage tray design is "ideal"

2. the lower(steel pan) is tilted with the motor so the sump pickup has to be cut and rotated, then modify a lower pan.

3. Last but not least. kiss your sway bar goodbye.

Re: Zerb's 90Q...07K it is

Posted: Mon Mar 17, 2014 3:41 pm

by Zerb

glibobbo21 wrote:been there with trying to mod a subframe for the old pan...couple issues I saw.

1. the engine does not stand almost vertical like the vw did. so i dont know the the windage tray design is "ideal"

2. the lower(steel pan) is tilted with the motor so the sump pickup has to be cut and rotated, then modify a lower pan.

3. Last but not least. kiss your sway bar goodbye.

1. Solid point. I haven't a clue either. Lol

2. I see what you're saying now by looking at the motor back together on the engine stand. Does the motor fit in the car with just the upper pan attached? Did you hack a subframe and then conclude it wasn't possible?

3. Wouldn't be terribly terribly upset without a front sway bar. Car as you know is street driven when it's together. But it's main purpose is going fast in a straight line, front sway bar isn't critical for that.

Semi proposed plan for subframe. Although I would do it out of 2x3 rectangular steel versus tubing like this.

Sent from my SAMSUNG-SM-N900A using Tapatalk

Re: Zerb's 90Q...07K it is

Posted: Mon Mar 17, 2014 3:46 pm

by 20VAvant

Zerb wrote:not exactly perfect, but the idea is there just for proof of concept...and its always fun to learn some more solidworks

forgot to add the -6 bung for the tstat bypass. and the hole for the coolant temp sensor. hopefully getting some parts cut this week and can begin making this stuff a reality.

annnnnnnnnnnnnd, this is the beginning of the tstat housing base.

You can also apply cosmetic threads to the surface if you don't want to spend time cutting in threads.

Re: Zerb's 90Q...07K it is

Posted: Mon Mar 17, 2014 4:25 pm

by glibobbo21

I hacked a subframe for mockup while I waited for a pan. NO IT WILL NOT FIT(with just upper).

Dont forget bolts pass through the upper pan through the bell housing so you cant remove the pan with a trans on. Ask me how i know!!

Re: Zerb's 90Q...07K it is

Posted: Mon Mar 17, 2014 4:26 pm

by glibobbo21

and thats prob still not low enough

I know..crazy

Re: Zerb's 90Q...07K it is

Posted: Mon Mar 17, 2014 4:52 pm

by Zerb

oh i know how you know, you he-manned it off to get the motor in the car i saw in your build thread. i guess what ill have to do it get the motor in the car on the mounts, and drop the subframe...measure what i need to gain, and then go from there. wouldnt wanna cut a subframe then still not have the space i need.