The little 9xXX lathes are pretty useful little machines. There are a lot of different retailers with minor differences, but they are all essentially the same machines. I've had this Enco 9x21 for almost 15 years and its been a great little starter machine.

I've got a couple recommendations for anyone reading that either has one or is thinking about one.

Tooling:

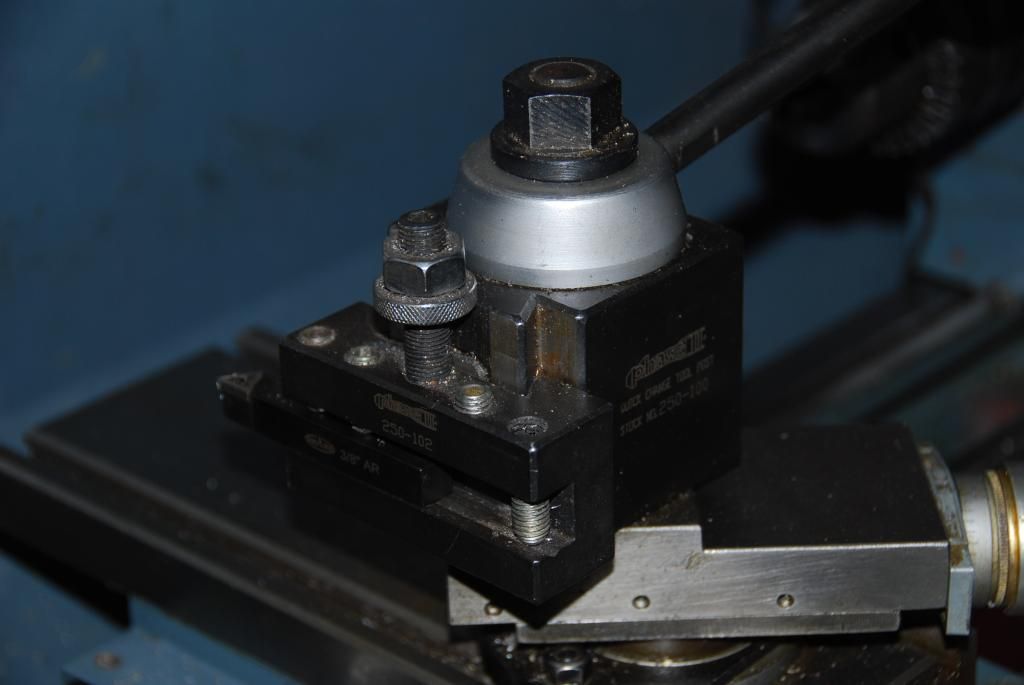

Get a quick change tool post (like Aaron has above also). I can change tools 2 or three times in a minute or two while working on things trying to get into the face,OD,ID,etc., and not having a quick change tool post is a PITA. It is probably the number one thing to get.

Indexable tooling (holders and inserts) sure beats constantly grinding tools for everything. You will still want to have some HSS or carbide blanks around to grind for special situations, but the indexable tooling will get you there 90+% of the time.

DRO:

You can add inexpensive DRO's by using the cheap digital linear scales like those used in the digital calipers. I added one to the carriage slide and one to the cross slide. I also will use dial indicators as a back-up sometimes, but the digital DRO's are usually within a couple thou even with my rickety brackets. There are also ones with remote and/or larger displays but these I've shown can be done on the super cheap...like less than $75 total for both axes.

Motor/Speed Controller:

Out of the box, these machines have a switch that is forward/reverse/off and the speeds are all changed via belts and pulleys. First, changing belts and pulleys is dirty and also a bit of a pain. Second, if you are doing things like single point threading and using the auto feed on the carriage, the lowest speed will still test your reflexes while threading up against a shoulder. The solution was a DC treadmill motor driven by a router speed controller. Now I rarely have to mess with the belts and just use the controller to adjust speed. The belts need to be changed on the rare occasions if you want/need to operate in a better spot on the motors torque/speed curve.

Looking forward to more updates and how the shop progresses!